Description

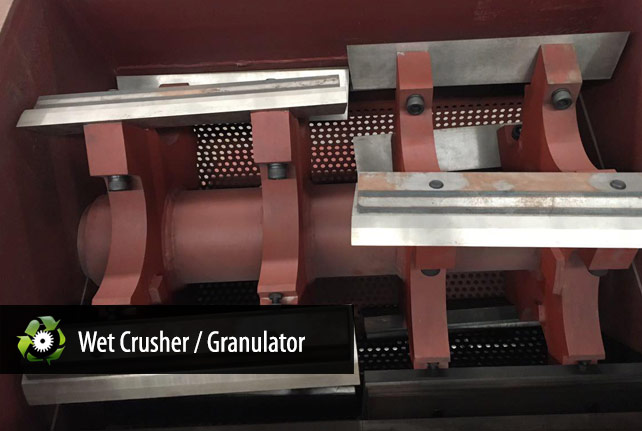

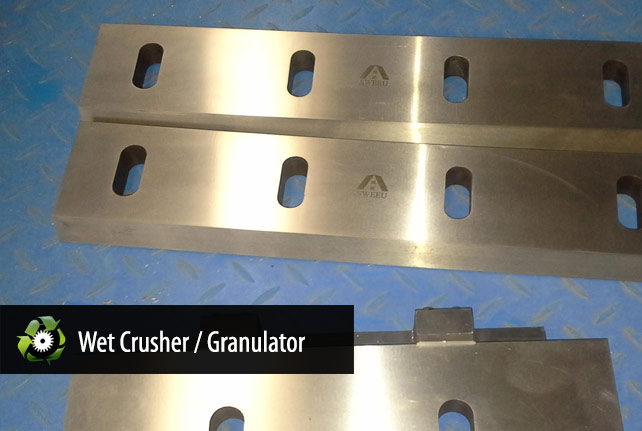

Wet Crusher /Granulator operates at much higher speeds, around 200-800 rpms. Heavy-duty knives are mounted at an angle (often times adjustable) on an open, hollow rotor in various arrays. When the blades on the fast spinning rotor makes contact with the stationary blades on the granulator housing, the feed stock is cut into relatively fine flakes or regrinds. At the bottom, or surrounding the spinning rotor is a sizing screen, a metal screen with holes the size of your desired output. The plastic film remains in the cutting chamber until it reaches the desired size, usually between several inches down to 1/8 of an inch, and falls through.

How It Works

For the purpose of washing plastic film/PET bottles, most will suggest the use of a wet crusher/granulator. Wet crushers/granulators work in the same fashion except with a constant stream of water being sprayed into the cutting chamber. This setup is ideal in most plastic film and bottle washing lines because it not only accomplishes size reduction, the added water helps to initially clean or “pre-treat” dirty plastics before it reaches another set of washing equipment. The added water also acts as a lubricant for the rotating blades to reduce heat and friction, allowing the blades to last much longer before sharpening.

Although plastic granulators offer the unique ability to produce smaller sized outputs, the fast moving parts make granulators very noisy to work with and produces high amounts of dust or fines. Manufacturers of higher quality granulators often offer the option of a soundproofing outer case and methods for dust/fines reduction through the use of added screens, reduced speeds, vacuums, and wet granulation.

Models & Specifications

| Model #: | Rotor Diameter: | Knife Width: | Rotating Speed: | Motor Power: | Capacity: |

| SWP630-1000 | ⌀630mm | 1000mm | 470 rpm | 55 KW | 1000 kg/h |

| SWP630-1200 | ⌀630mm | 1200mm | 470 rpm | 55 KW | 1200 kg/h |

| SWP700-1000 | ⌀700mm | 1000mm | 470 rpm | 75 KW | 1500 kg/h |

| SWP700-1200 | ⌀700mm | 1200mm | 470 rpm | 75 KW | 1800 kg/h |

| SWP800-1000 | ⌀800mm | 1000mm | 470 rpm | 90 KW | 2000 kg/h |

| SWP800-1200 | ⌀800mm | 1200mm | 470 rpm | 90 KW | 2500 kg/h |

Additional Images

Place An Order

The general lead time for all single-piece, standard equipment orders is 30 days. For custom orders or complete washing lines, the lead time is between 60 – 90 days. The actual lead time will depend heavily on the complexity of the project as well as the amount of machinery we have in queue at the time of your order.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.