Description

The trommel separator is excellent for removing small contaminants such as glass, metals, wood, paper/cardboard, and others before the plastic bottles are granulated. On top of its applications in PET recycling, the trommel separator is often found being used in municipal waste separation.

How It Works

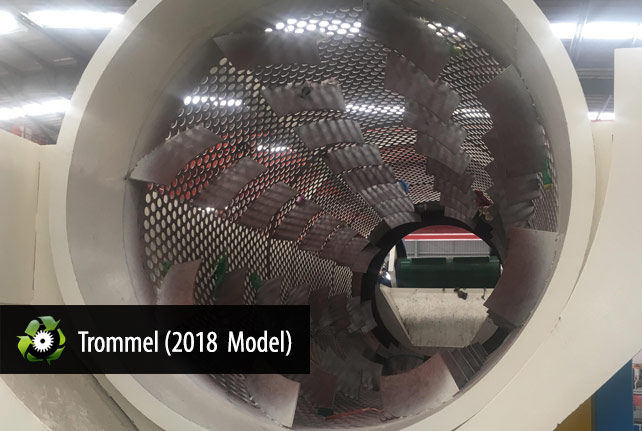

The trommel is a large cylindrical mesh screen tunnel that slowly rotates. To transmit the PET bottles forward, the trommel is set at a tilt and flaps are added on the interior to continuously flip and guide the PET bottles in a forward motion. As the PET bottles slowly moves through this large piece of separation equipment, small pieces of unwanted contamination such as broken glass falls through the mesh screen and is collected. The holes on the screen are small enough so PET bottles do not fall through.

The trommel is a large cylindrical mesh screen tunnel that slowly rotates. To transmit the PET bottles forward, the trommel is set at a tilt and flaps are added on the interior to continuously flip and guide the PET bottles in a forward motion. As the PET bottles slowly moves through this large piece of separation equipment, small pieces of unwanted contamination such as broken glass falls through the mesh screen and is collected. The holes on the screen are small enough so PET bottles do not fall through.

Specifications

ASG offers a standard trommel that is 1500mm in diameter and 4500mm long with automatic brush units to keep the mesh filters clean. Depending on your requirements, ASG can also provide trommels made to your specifications.

| Diameter: | φ1500㎜ |

| Trommel Length: | 4500㎜ |

| Material: | Carbon Steel |

| Tilt Angle: | 5° |

| Motor Power: | 5.5 KW |

| Reduction Ratio: | 1:17 |

Additional Images

Place An Order

The general lead time for all single-piece, standard equipment orders is 30 days. For custom orders or complete washing lines, the lead time is between 60 – 90 days. The actual lead time will depend heavily on the complexity of the project as well as the amount of machinery we have in queue at the time of your order.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.