This is a standard 1,500-2,000 KG/H PET bottle washing line we designed for a client in the U.S.A and can reach slightly higher capacities if we upgrade several pieces of equipment.

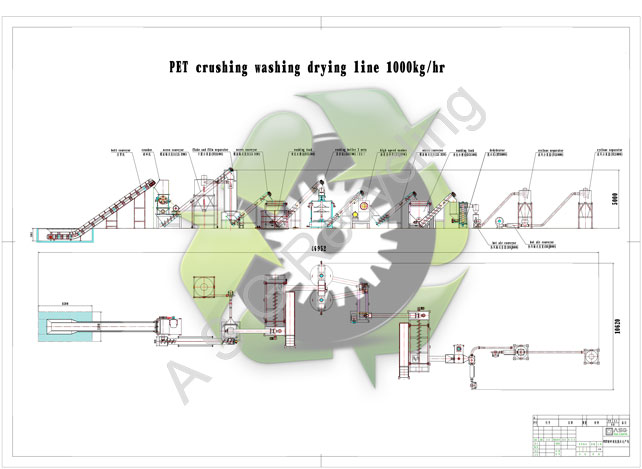

PET Washing Line Diagram

Machinery List / Specifications / Quotation

| Machine Description | Specifications |

| 1. Belt conveyor (PSL-1000, 1 set) |

1) belt width: 1000㎜ 2) belt material: PVC 3) motor power: 3.7KW 4) reduction ratio: 1: 30 5) drive roll diameter; φ273㎜ 6) belt linear velocity 0.63m/s |

| 2. Bag opener(with bounce separator, CBJ, 1 set) |

1) power: 5.5kw 2) reduction ratio: 1:35 3) main shaft rotating speed: 42rpm 4) turning diameter: φ390㎜ 5) main machine material: Q235 6) putting platform dimension: 1900×2500㎜ 7) feeding mouth dimension: 1800×2200㎜ |

| 3. Belt conveyor (PSL-1000, 1 set) |

1) belt width: 1000㎜ 2) belt material: PVC 3) motor power: 3.7KW 4) reduction ratio: 1: 30 5) drive roll diameter; φ273㎜ 6) belt linear velocity 0.63m/s |

| 4. Wet Label remover (TB-800, 1 set) |

1) Drum diameter φ1000㎜ 2) Drum Length 4500㎜ 3) Rotary speed 500 5) Material 45 6) Motor power 22KW |

| 5. Belt conveyor (PSL-1000, 1 set) |

1) belt width: 1000㎜ 2) belt material: PVC 3) motor power: 3.7KW 4) reduction ratio: 1: 30 5) drive roll diameter; φ273㎜ 6) belt linear velocity 0.63m/s |

| 6. Sorting conveyor (FXPS, 1 set) |

A. Sorting conveyor, frequency control, 2 sets 1) belt width: 600㎜ 2) belt material: PVC 3) motor power: 1.5 KW 4) roller diameter: φ240㎜ 5) belt linear velocity 0-1.25m/s 6) belt conveyor length: 8000㎜ B. Reverse conveyor 1) belt width: 400㎜ 2) belt material: PVC 3) motor power: 1.5 KW 4) roller diameter: φ240㎜ 5) driven roller diameter: φ215㎜ 6) belt linear velocity 0-1.25m/s 7) belt conveyor length: 8000㎜ |

| 7. Belt conveyor (PS-800, 1 set) |

1) belt width: 800㎜ 2) belt material: PVC 3) motor power: 2.2KW 4) reduction ratio: 1: 30 5) drive roll diameter; φ273㎜ 6) belt linear velocity 0.63m/s |

| 8. Crusher (SWHB1000, 2 sets) |

1) main motor 75KW 2) cutter head rotary diameter: φ630㎜ 3) cutter head width: 980㎜ 4) No.of rotating knife: 10 pcs 5) No.of stating knife: 4 pcs 6) cutter material: SKD11 7) cutter head rotating speed: 462rpm 8) cutter head material: 45 steel 9) screen mesh: φ16㎜ 10) mechanical change screen: 0.75KW 11) capacity: 800-1000kg/h 12) transmission power: 2.2KW 13) gear reducer model: NMRV130-20 14) screw conveyor rotating speed: 72.5rpm 15) screw vane diameter: φ250㎜ 16) screw space: 200㎜ 17) screw material: stainless steel |

| 9. Screw conveyor 1 (LX-390, 1 set) |

1) motor power: 3.7KW 2) screw conveyor rotating speed: 20-72.5rpm adjustable 3) screw vane diameter: φ390㎜ 4) screw stroke: 300㎜ 5) screw material: stainless steel 6) frame material: carbon steel |

| 10. Washing tank (QXC1500, 1 set) |

1. Width inside: 1500㎜ 2. Total length: 4500㎜ 3. Material: stainless steel 4. Frame material: carbon steel 5. Bottom screw motor: 5.5KW 6. Lifting dirt screw motor power: 3.7KW (one of it’s frequency control) 7. Main motor power: 0.37KW 8. Well distributed motor power 2.2KW |

| 11. Cooking Boiler (ZG1700, 2 sets) |

1) motor power: 7.5KW 2) reducer model: BLD5-71-7.5 3) agitating shaft rotating speed: 20rpm 4) boiler material: stainless steel 5) transmission power: 3.7KW 6) reducer model: NMRV110-20 7) screw rotating speed: 20-72.5rpm, frequency control 8) screw vane diameter: φ287㎜ 9) screw spacer: 200㎜ 10) screw material: stainless steel |

| 12. High speed Friction machine (HXJ800, 1 set) |

1) rotor rotary diameter: φ524㎜ 2) rotor material: carbon steel 3) rotor rotating speed: 960rpm 4) No. of rotor vane: 24 pcs 5) washer body: stainless steel 6) effective washing length: 2800㎜ 7) motor power; 45KW 8) conveying angle: 15° 9) driving way: belt drive |

| 13. Screw conveyor 1 (LX-390, 1 set) |

1) motor power: 3.7KW 2) screw conveyor rotating speed: 20-72.5rpm adjustable 3) screw vane diameter: φ390㎜ 4) screw stroke: 300㎜ 5) screw material: stainless steel 6) frame material: carbon steel |

| 14. Washing tank (QXC1500, 1 set) |

1. Width inside: 1500㎜ 2. Total length: 4500㎜ 3. Material: stainless steel 4. Frame material: carbon steel 5. Bottom screw motor: 5.5KW 6. Lifting dirt screw motor power: 3.7KW (one of it’s frequency control) 7. Main motor power: 0.37KW 8. Well distributed motor power 2.2KW |

| 15. Dewatering machine (HTS800, 1 set) |

1) main motor power: 45KW 2) machine inside material: stainless steel 3) rotor rotary diameter: φ850㎜ 4) rotor material: carbon steel |

| 16. Hot air conveyor (RSJ800, 1 set) |

1) pipe diameter: φ159㎜ 2) blower power: 5.5KW 3) pipe material: stainless steel 4) blower model: 6-30 -4.7A 5) heating power: 48KW |

| 17. Finished product Silo (LC-2, 1 set) |

1) silo material: stainless steel 2) silo volume: 2.5m3 |

| Capacity: 1,500 -2,000 KG/h | Price: $320,000 |

Ordering

- Quotation is for FOB Port of Shanghai.

- Payment Terms: 30% of the total contract price as down payment (T/T). The balance 70% of total contract price should be paid upon picking up the goods (T/T).

- Delivery: 60-90 working days after receiving the down payment.

- Price Validity: Prices listed on this webpage are a close approximation only. Final contract value will be determined based on your specifications.

- Warranty: One Year

- Packing: Wooden Cases

- The spare parts are available upon request.