Applications

This shredder can process a wide range of materials including rubber blocks, cables, waste plastics, etc…

How it works

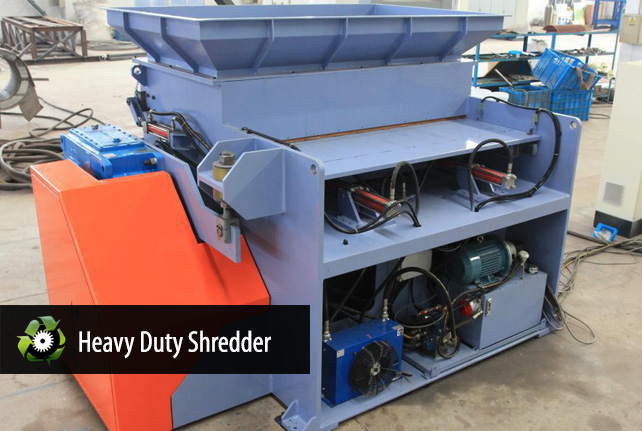

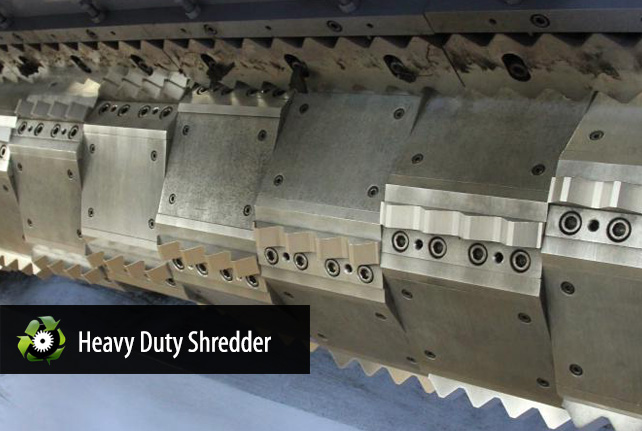

Our shredders use unique, three-teeth knives that are bolted securely onto a large, closed rotor in a staggered array. As the three-teeth rotor knives are mounted with the corners protruding, jagged-teeth knives are mounted within the cutting chamber that act as the stationary knives. As material is fed into the shredder, a hydraulic assisted drawer pushes the material against the rotor where it will be continuously cut until it reaches the desired size as designated by a screen filter that is fitted beneath the cutting chamber; The material will continue to be shredded until it is small enough to fall through this screen filter.

As our shredders are often times placed in front of the most demanding jobs, the frame and structure of our shredders use high-thickness sheets and tubular. The square knives are treatment strengthened and use only the highest quality SKD11 steel (D2 equivalent) to ensure against dulling. Depending the capacity you require, we offer a variety of standard tires shredders for your choosing.

Features

- Highly resistant hooks – high resistance to wear, may be welded again, optimized shredding geometry

- Housing in two parts – easy and quick exchange of the whole shafts possible by simple unscrewing of the superior element of the housing

- High sealing for bearings – quadruple sealing preventing leakages, even for liquids

- Shock absorbers – efficient protection system of the hydraulic drive against overloads

- Hydraulic drive – special design hydraulic drive for optimal torque and performance, works perfectly in extreme conditions

Specifications

| Model # | Motor Power | Shaft Diameter | Rotary Speed | Capacity |

| SSJ-1000 | 45KW | ⌀450mm | 55 rpm | 1000 kg/h |

| DS2000 | 110KW | ⌀500mm | 45 rpm | 3000 kg/h |

| DS3000 | 2*110KW | ⌀500mm | 40 rpm | 5000 kg/h |

Additional Images

Place an Order

The general lead time for all single-piece, standard equipment orders is 30 days. For custom orders or complete washing lines, the lead time is between 60 – 90 days. The actual lead time will depend heavily on the complexity of the project as well as the amount of machinery we have in queue at the time of your order.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.