Description

The hot washer for PET flakes is the heart of the PET bottle washing line capable of getting rid of hard to remove contamination such as glues, oils, grease, and left-over foods/liquids. For PET recycling, the hot water washing process is essential step in producing high-quality “hot washed” PET flakes that sell for much higher prices.

How It Works

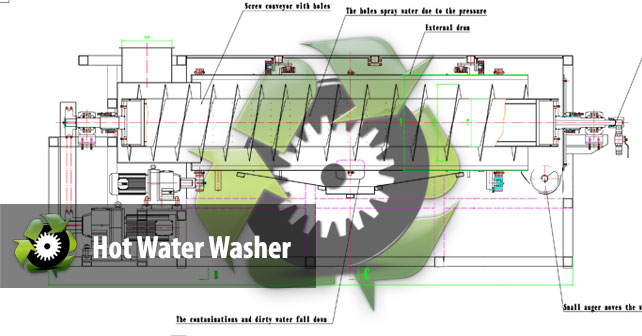

Unlike any other hot washers in the market today, our patented hot washer design uses a large screw auger to transmit PET flakes horizontally through a boiling water bath. This energy-efficient design makes use of tiny holes on the transmit auger that directly sprays hot water onto the PET flakes from the interior.

Surrounding the screw auger is a large mesh screen tunnel which keeps the PET flakes in place while smaller contaminants fall through. A diagram of our hot washer has been provided below.

Models & Specifications

| Model #: | Main Motor Power: | Shaft Rotation Speed: | Boiler Material: | Conveyor Power: | Conveyor Speed: |

| ZG1700 | 7.5KW | 20 RPM | Type 304 Stainless Steel |

3.7KW/H | 20-80 RPM Frequency Controlled |

Additional Images

Place An Order

The general lead time for all single-piece, standard equipment orders is 30 days. For custom orders or complete washing lines, the lead time is between 60 – 90 days. The actual lead time will depend heavily on the complexity of the project as well as the amount of machinery we have in queue at the time of your order.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.