This is a standard 500 KG/H PET bottle washing line we designed for a client in the U.S.A and can reach slightly higher capacities if we upgrade several pieces of equipment.

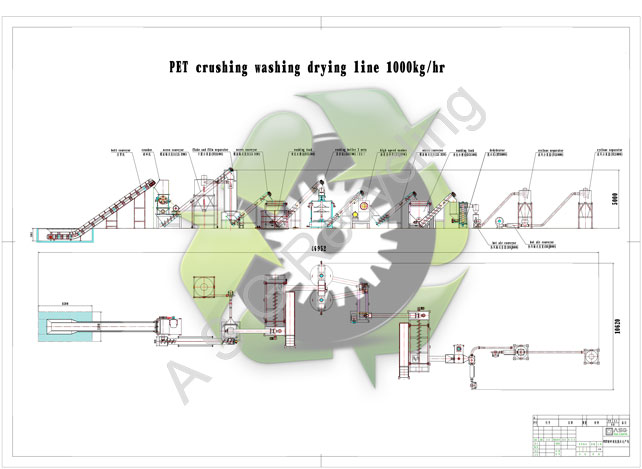

PET Washing Line Diagram

Machinery List / Specifications / Quotation

| Machine Description | Specifications |

| 1. Belt Conveyor (1 set) |

Carrying the bottles into label remover Width of belt: 590mm Basic material of belt: 3mm PVC Motor power and brand: 2.2KW Dazhong Length of transportation:4500mm With magnetic drum The thickness of steel plate:3mm |

| 2. Bottle label remover (1 set) |

Removing the labels from bottles Motor power and brand: 18.5KW Dazhong Roller diameter: 800mm Length: 2500mm The parts in contact with material are made from Stainless steel. Overall size:2500*1200*1800mm(L*W*H) Weight:1900kg The thickness of steel plate:6mm |

| 3. Manual sorting conveyor (1 set) |

Separate the bottles in color or PVC bottles by hands Belt width: 800mm Belt Length: 6000mm Motor power and brand:2.2KW Dazhong Size: 6000*800*1200mm Weight: 890kg Belt thickness: 3mm The thickness of steel plate: 3mm |

| 4. Belt conveyor (1 set) |

Waste bottles feeding Width of belt: 690mm Basic material of belt: PVC Motor power and brand: 1.5KW Dazhong Length of transportation:4500mm Belt thickness:3mm The thickness of steel plate:3mm |

| 5. Crusher (1 set) |

Bottle size reduction Motor power and brand: 37KW Dazhong Diameter of hole of screen sieve:17mm Cover opening: electrical Qty. of rotary blades: 10 pc Qty. of stationary blades: 4 pc Basic material of blades: SKD11 Rotation speed of blade: 462RPM The thickness of steel plate:30mm |

| 6. Screw conveyor (1 set) |

PET flakes transfer Motor power: 3KW Dia. of screw: 300mm Effective length:3300mm Part contact with raw material: stainless steel |

| 7. Floating washer (1 set) |

Cleaning flakes and separating most contamination and caps via density Width : 1320mm Effective length:4500mm Power of pushing drum:3KW*2 Motor power of bottom screw: 2.2KW Diameter of screw:300mm Part contact with raw materials: 3mm stainless steel Lifting screw motor power:3KW Lifting screw diameter:300mm Lifting Screw length:3300mm Lifting screw Material:4mm Stainless steel Motor brand:Dazhong |

| 8. Hot washer (1 set) |

Clean the PET flakes via hot water Motor power and brand: 7.5KW Dazhong Dimension of hot washer: 1650mm Volume of hot chamber≈4.5m3 Part contact with raw materials: 3mm stainless steel |

| 9. Screw conveyor (1 set) |

PET flakes conveyed into high speed friction washer Motor power and brand: 3KW Dazhong Dia. of screw:300mm Effective length:3200mm Part contact with raw materials: 4mm stainless steel |

| 10. High speed friction washer (1 set) | Clean the flakes via friction Motor power and brand: 30KW Dazhong Rotary speed of screw: 1440Rpm Part contact with raw materials: stainless steel The thickness of steel plate:3mm |

| 11. Floating washer (1 set) |

Cleaning flakes and separating most contamination and caps Width : 1320mm Effective length:4500mm Power of pushing drum:3KW*2 Motor power of bottom screw: 2.2KW Diameter of screw:300mm Part contact with raw materials: 3mm stainless steel Lifting screw motor power:3KW Lifting screw diameter:300mm Lifting Screw length:3300mm Lifting screw Material:4mm Stainless steel Motor brand:Dazhong |

| 12. Dewatering machine(1 set) | Dry the PET flakes via centrifugal force Motor power: 7.5KW Rotary speed: 1440rpm The power of pushing screw:1.5KW Part contact with raw materials: 3mm stainless steel |

| 13. Hot air dryer (1 set) |

Hot air drying Heating power: 36KW Motor power: 7.5KW Dazhong Pipe diameter:168mm Pipe material:1.5mm Stainless steel |

| 14. Label separator (1 set) |

Removing the left labels or dust via air suction Motor power of air blower: 7.5KW Motor power of air suction:4KW Part contact with raw materials: 5mm stainless steel |

| 15. Finished product silo (1 set) |

Storage silo for PET flakes Material of storage silo: 2mm stainless steel Volume:2m3 Part contact with raw materials: stainless steel |

| 16. Electric cabinet | Electric control for the whole ine Electric control component: SIMENS,TECO and DELIXI Motor brand for the whole line:Dazhong |

| Capacity: 500 KG/h | Price: $160,000 |

Ordering

- Quotation is for FOB Port of Shanghai.

- Payment Terms: 30% of the total contract price as down payment (T/T). The balance 70% of total contract price should be paid upon picking up the goods (T/T).

- Delivery: 60-90 working days after receiving the down payment.

- Price Validity: Prices listed on this webpage are a close approximation only. Final contract value will be determined based on your specifications.

- Warranty: One Year

- Packing: Wooden Cases

- The spare parts are available upon request.